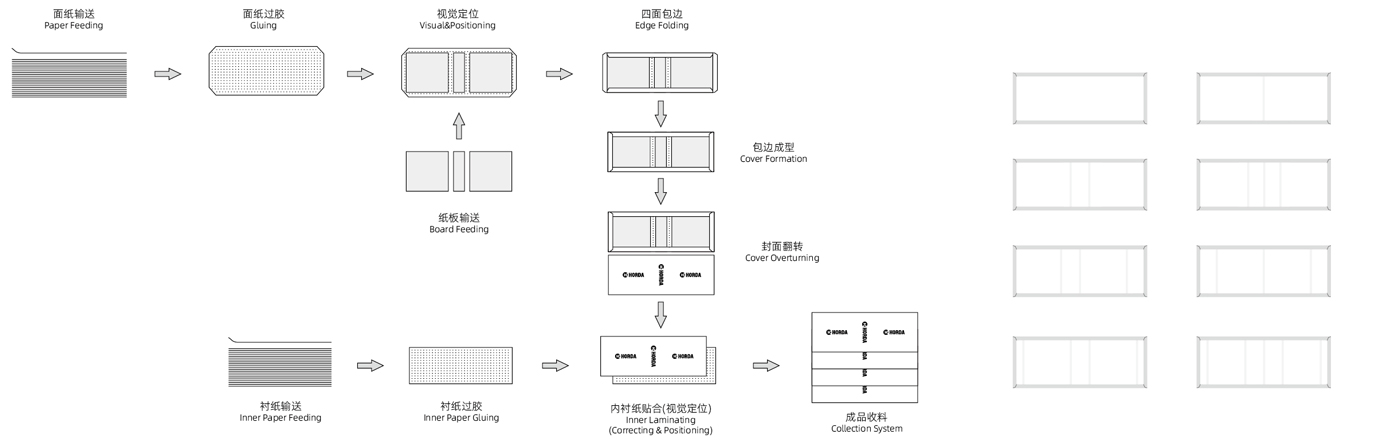

QZFM-700B Automatic Case Making & inner Laminating Machine (CCD) is upgrade and optimization based on Automatic Case Making & Inner Laminating Machine ,which can finish four-side folding and inner paper laminating at one time, filing the market gap of mutifunctional case maker. lt's a machine with high quality, high accuracy, high speed and low labor during production.lt can be applied for high volume packaging material production of moon cake, tea, cellphone, underwear, handicraft products cosmetics, folder, calendar, hard cover books and so on.

| Model | QZFM-700A | QZFM-1000A | QZFM-700B | |

| Maximum size | mm | 450×700 | 600×1050 | 450×700 |

| Minimum size | mm | 100×200 | 140×240 | 120×180 |

| Paper weight | g | 100-200 | 100-200 | 100-200 |

| Board thickness | mm | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 |

| Boards amount | Pieces | 1-6 | 1-6 | 1-6 |

| Speed | Pieces/min | 15-25 | 15-25 | 20-30 |

| Positioning accuracy | mm | ±0.2 | ±0.2 | ±0.15 |

| Power supply | kw | 30 | 34 | 38 |

| Weight | kg | 6500 | 9000 | 8000 |

| Dimension | mm | 12000×6200×1850 | 15000×7900×1900 | 11500×7500×1850 |

(Not standard with machine, please choose freely according to actual needs):

1.Viscosity controller Can automatically add water and keep it at a stable viscosity value, good help for user without experience of using case maker.

2.Cold glue(white glue) system Equipped with a glue pump especially for cold glue use, can satisfy customer’s requirements of making various products.

3.Bottom-suction device Used at inner lining process, fitting for the products with the cover material easily scratched, bottom suction device feeds the board from bottom, can 100% avoid the scratches on product surface.

4.Soft Spine device It’s specially designed for hardcover book manufacturers.The minimum spine thickness:≥ 250g, minimum width: 15mm.