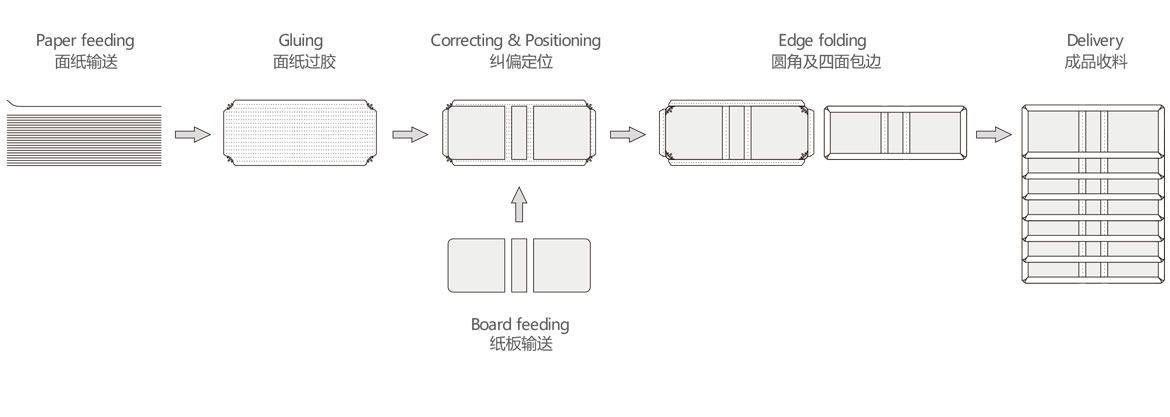

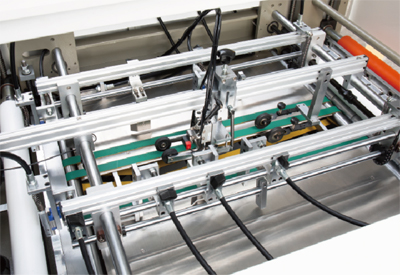

ZFM-700/1000/1 350A Automatic Hardcover Case Making Machine has the functions including case making and inner laminating. Speed up to 30 pieces/min. Energy consumption 60% lower.

The finished product size is as large as 1350x600mm

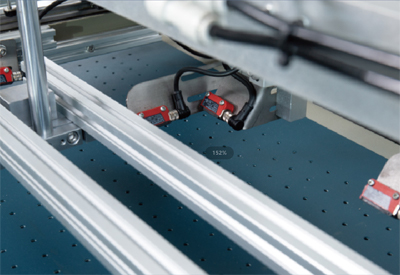

The positioning accuracy is up to ±0.2mm

The adjustment speed is as fast as 20~30 minutes

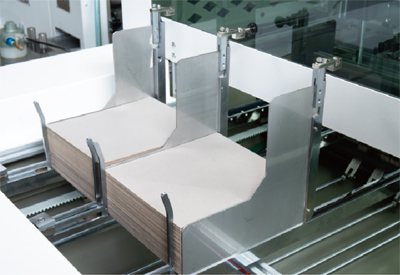

It can be used to make triangle, “S” shape, curve etc.

irregular shape products without any mould.

It makes production more effective,

not only saves cost, but also saves time and energy.

The glue tank with heat preservating and automatic recycling function, saves energy for 60% comparing with traditional glue tank.

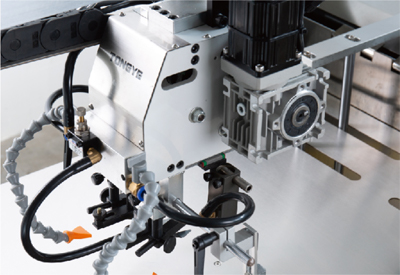

Japanese Panasonic PLC, Frequency converter

Japanese Panasonic servo motor

Japanese NSK Bearings

Japanese ORION Vacuum Pump

Taiwan PMI Linear Slideway

Japanese CKD pneumatic element

German LEUCE photosensor

Airtac Pneumatic Component

Advanced wear-resistant automotive

French Schneider electric

Taiwan ADLEE DC motor

| Model | ZFM-700A | ZFM-1000A | ZFM-1350A | |

| Maximum size | mm | 450×720 | 600×1050 | 750×1350 |

| Minimum size | mm | 90×180 | 140×240 | 140×240 |

| Paper weight | g | 105-210 | 105-210 | 105-210 |

| Board thickness | mm | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 |

| Boards amount | Pieces | 1-6 | 1-6 | 1-6 |

| Minimum spine width | mm | 8 | 8 | 8 |

| Minimum side-board width | mm | 25 | 25 | 25 |

| Speed | Pieces/min | 20-30 | 15-25 | 15-25 |

| Positioning accuracy | mm | ±0.2 | ±0.5 | ±0.5 |

| Power supply | kw | 16 | 18 | 19 |

| Weight | kg | 3500 | 5000 | 6000 |

| Dimension | mm | 8500×2600×1500 | 10440×3000×1500 | 11500×3000×1500 |

(Not standard with machine, please choose freely according to actual needs):

1.Viscosity controller Can automatically add water and keep it at a stable viscosity value, good help for user without experience of using case maker.

2.Cold glue(white glue) system Equipped with a glue pump especially for cold glue use, can satisfy customer’s requirements of making various products.

3.Bottom-suction device Used at inner lining process, fitting for the products with the cover material easily scratched, bottom suction device feeds the board from bottom, can 100% avoid the scratches on product surface.

4.Soft Spine device It’s specially designed for hardcover book manufacturers.The minimum spine thickness:≥ 250g, minimum width: 15mm.