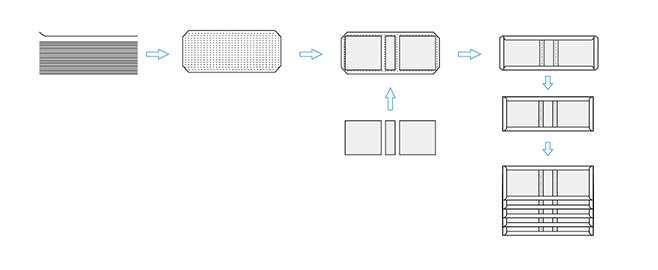

ZFM-700/1000H Automatic Calendar Cover Making Machine is a product developed byour company to meet the diversified needs of the market for packaging boxes. The equipment adopts motion controler and production speed of 35 pcs/min.

Adopt motion controller, running speed up to 35pcs/min

Equipped with intelligent glue tank

Photoelectric sensor detection

Servo corrective positioning.

Increase the direction of the conveyor belt secondary positioning, positioning accuracy is higher ± 0.2mm.

Can be double-head heterogeneous edging, double-head narrow edges can be done 18mm.

Equipped with Internet of Things module.

Edge-beating corner positioning servo detection.

| Model | ZFM-700H | ZFM-1000H | |

| Maximum size | mm | 450×720 | 600×1050 |

| Minimum size | mm | 90×180 | 120×240 |

| Paper weight | g | 105-210 | 105-210 |

| Board thickness | mm | 1.0-3.0 | 1.0-4.0 |

| Boards amount | Pieces | 1-6 | 1-6 |

| Minimum spine width | mm | 8 | 8 |

| Minimum side-board width | mm | 25 | 18 |

| Speed | Pieces/min | 20-30 | 25-35 |

| Positioning accuracy | mm | ±0.2 | ±0.2 |

| Power supply | kw | 16 | 24 |

| Weight | kg | 3500 | 6000 |

| Dimension | mm | 8500×2600×1500 | 10100×3000×2000 |

(Not standard with machine, please choose freely according to actual needs):

1.Viscosity controller Can automatically add water and keep it at a stable viscosity value, good help for user without experience of using case maker.

2.Cold glue(white glue) system Equipped with a glue pump especially for cold glue use, can satisfy customer’s requirements of making various products.

3.Bottom-suction device Used at inner lining process, fitting for the products with the cover material easily scratched, bottom suction device feeds the board from bottom, can 100% avoid the scratches on product surface.

4.Soft Spine device It’s specially designed for hardcover book manufacturers.The minimum spine thickness:≥ 250g, minimum width: 15mm.