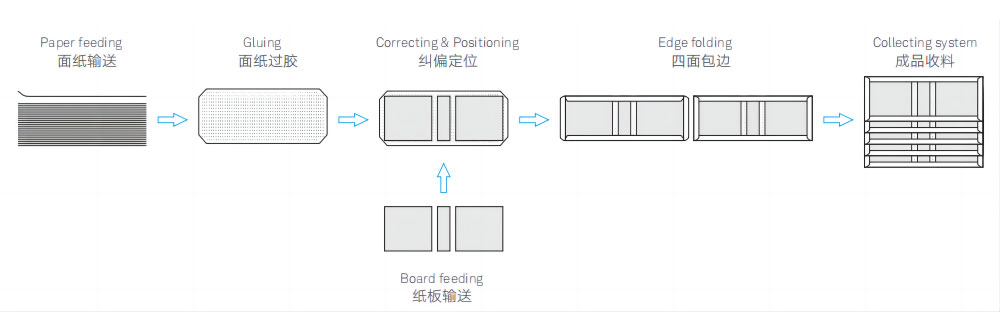

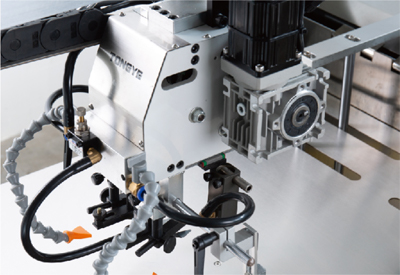

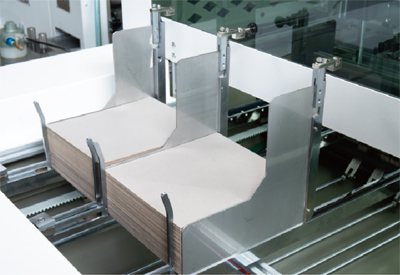

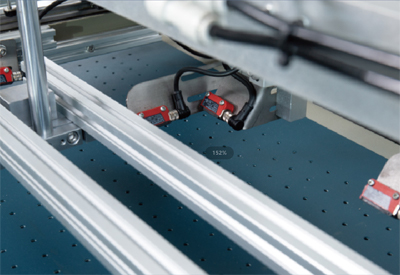

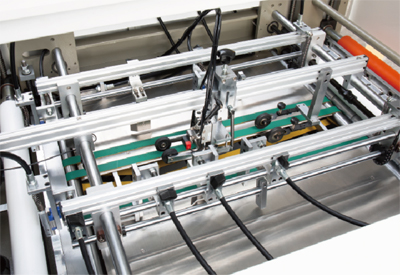

ZFM-700K fast speed Automatic case making machine adopts a motion control system to increase the production speed to 35 pieces/min. It uses servo drive, photoelectric detection, servo positioning and other technologies. The machine uses 9 servo systems to automatically complete paper feeding, gluing, cardboard positioning, four-side folding and other processes with high precision, fast speed and high quality.

High Stability

Long Service Life

High Precision

Fast Debugging

Prevent Scratches

| Model | ZFM-700K | |

| Maximum size | mm | 450×720 |

| Minimum size | mm | 90×180 |

| Paper weight | g | 105-210 |

| Board thickness | mm | 1.0-3.0 |

| Boards amount | Pieces | 1-6 |

| Minimum spine width | mm | 8 |

| Minimum side-board width | mm | 25 |

| Speed | Pieces/min | 20-35 |

| Positioning accuraCy | mm | ±0.2 |

| Power supply | kw | 16 |

| Weight | kg | 3500 |

| Dimension | mm | 8500×2600×1500 |

(Not standard with machine, please choose freely according to actual needs):

1.Viscosity controller Can automatically add water and keep it at a stable viscosity value, good help for user without experience of using case maker.

2.Cold glue(white glue) system Equipped with a glue pump especially for cold glue use, can satisfy customer’s requirements of making various products.

3.Bottom-suction device Used at inner lining process, fitting for the products with the cover material easily scratched, bottom suction device feeds the board from bottom, can 100% avoid the scratches on product surface.

4.Soft Spine device It’s specially designed for hardcover book manufacturers.The minimum spine thickness:≥ 250g, minimum width: 15mm.